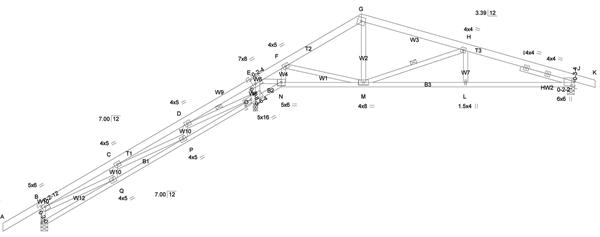

I chose to frame the roof with an engineered wood truss, which forms both an attic and vaulted ceiling. I chose a truss, rather than a traditional 2x roof rafter, to more easily achieve my efficiency goals. Over the vaulted ceiling area, I wanted the truss to accommodate 18” of cellulose insulation – about R-65. Because the truss has separate elements – a 2×6 top chord and 2×4 bottom chord and supporting elements – insulation can fill the spaces in-between, which prevents thermal bridging, or “heat bleed” through the wood, which is a poor insulator.

The attic area is too small for storage space so we simply blew in cellulose to a depth of 24” – about R-86. On one side of the attic, the cellulose is continuous with the cathedral ceiling. On the other side, it terminates against the front wall where I have 12” between the attic floor and the roof sheathing. 12” of cellulose works out to R-43, sufficient to keep the roof cold, thereby avoiding ice dams in winter.

To satisfy the air-tight requirement, we attached ½” plywood to the interior underside of the roof trusses and then taped all of the joints with a European flashing tape which will adhere tenaciously to the plywood for as long as the home stands. Where this interior plywood meets the exterior plywood sheathing on the walls, we used a wider flashing tape to seal this critical joint.

We used flashing tape at all other intersections of floor, wall, and roof planes, as well as to install the windows and doors. The end result is a very, very air-tight house, as demonstrated by a third-party blower door test result of 0.46, which easily meets the PH certification standard of 0.6 ACH50 (air changes per hour at a 50 pascal air pressure difference between inside and outside the house). The current code requirement in CT is 7.0ACH50, nearly twelve times the PH standard. This is yet another instance where the code standard for this critical efficiency element is well behind the times.