Double wall construction is a common green building method and best practice for building walls that are part of the home’s thermal envelope.

Your home’s thermal envelope is arguably the most important aspect of making a home energy efficient and comfortable and is also a key element in making a green home a healthy home.

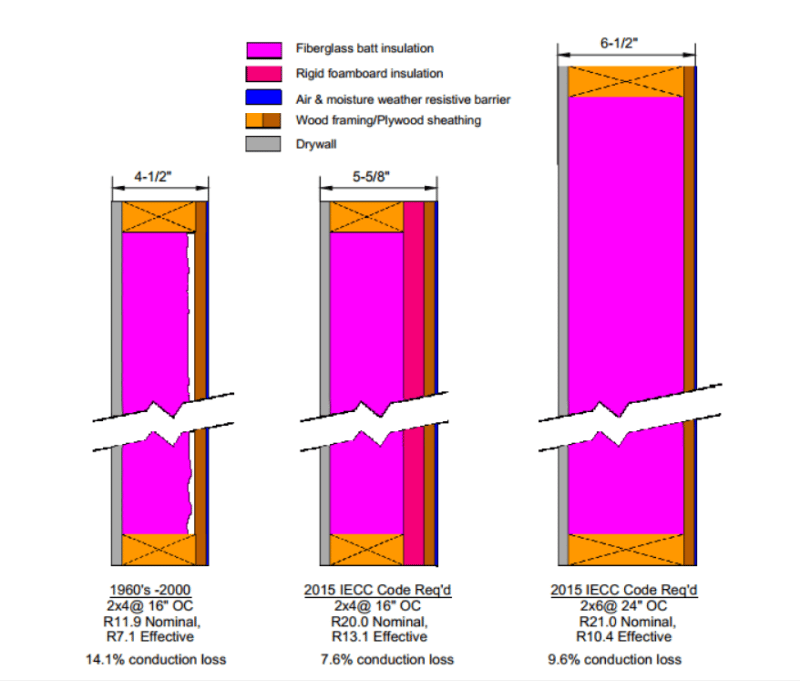

Samples of Single Wall Construction for Comparison

Single wall construction is typically the wall construction called for in building codes. It should be remembered that building code is the minimum allowable level for a given component. In this case the minimum level of energy efficiency.

Figure 1: Typical Building Code Single Wall Construction Approaches

In figure 1 the first wall on the left has 2×4 stud construction typical of walls built to code between the 1960s and the early 2000s. The inside of the wall is drywall and the outside has plywood or OSB sheathing, at type of engineered lumber. On the exterior of the sheathing is an air and moisture resistant barrier. In between the sheathing and drywall is batt insulation, typically fiberglass.

There are a few problems with this first example wall construction.

- There is too little space for insulation to provide much energy efficiency.

- The 2×4 studs are in contact with the exterior and interior walls and allow for significant thermal bridging. Thermal bridging is an area that allows heat energy to flow from a warm place to a cold place. In this case in the winter, the 2×4’s will allow heat energy in the home to escape. In the summer the 2×4 will allow heat from the outside to get into the home causing the air conditioners to work longer to keep the home cool.

- With only 2×4 studs in a wall, they must be placed 16″ apart. To be exact, the center of each 2×4 must be 16″ apart which means less than 16″ of space between each stud for insulation and a large number of studs for thermal bridging.

In the middle wall example, there is a layer of rigid foam board between the sheathing and the studs. This helps reduce thermal bridging through the 2x4s, but there is still little room for insulation within the wall cavity.

The third single wall construction on the right is like the first but with 2 differences that improve the insulation value of the wall.

- The studs are 2×6 allowing for a thicker layer of insulation in the wall cavity

- Because the studs are 2×6 they can be placed 24″ on center leaving even more room for insulation and reducing the number of studs in the wall and so lowers the thermal bridging opportunities.

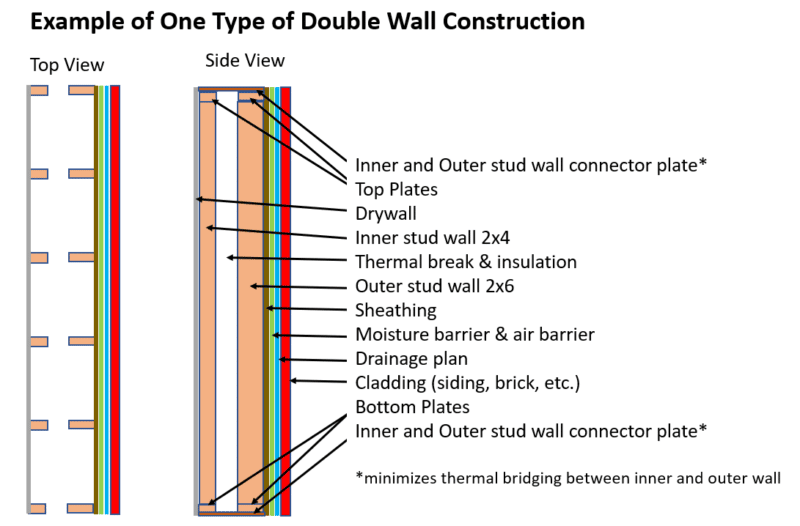

Sample of Double Wall Construction

Double construction is considered a best practice for walls that are part of a home’s thermal envelope.

Figure 2: Example of Double Wall Construction

Figure 2 shows one of many ways to approach double wall construction. In this example, the exterior wall uses 2×6 studs and the inner wall uses 2×4 studs. There is a gap between the two walls so that a large amount of insulation can be used. This gap can be any size required to provide the R-value of insulation needed. Typically the space between the drywall and sheathing for insulation is 9″ to 16″ but can be larger. Because the studs in the two walls don’t touch, there is no thermal bridging.

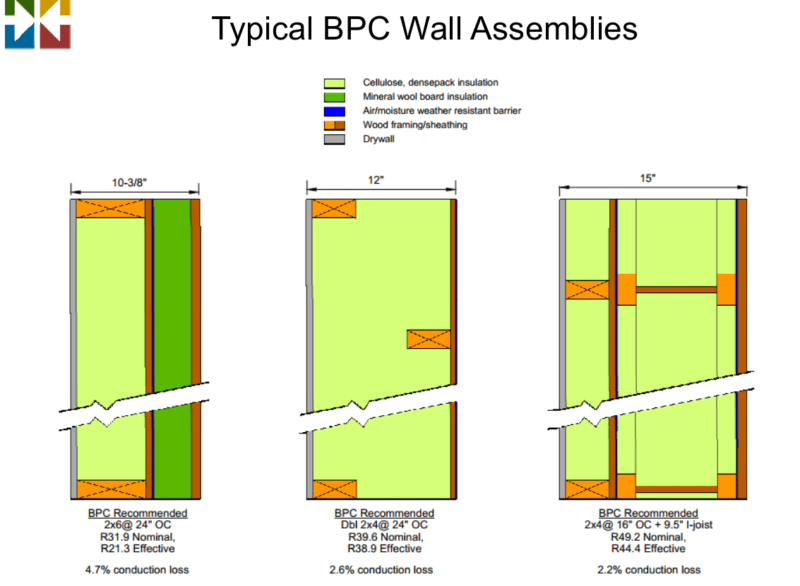

Figure 3: Examples of Typical BPC double wall Construction

Figure 3 shows some of the different ways BPC builds its walls.

The first example on the left is a single/double wall hybrid construction. It is a 2×6 wall with drywall, insulation, and sheathing. Then, a thick layer of rigid foam and an outer layer of sheathing.

The middle double wall uses 2x4s for both the inner and outer walls with a gap between them to allow for ample insulation between the walls and eliminates thermal bridging. The studs in the inner and outer wall are also staggered to allow more insulation around and between the studs.

The double wall on the right uses 2x4s for the inner wall with drywall on the inside and sheathing on the outside of the 2×4. Then the second wall is built using engineered lumber in the shape of an I beam. Because the middle part of the I beam is very thin and long there is little thermal bridging.

BPC builds double wall construction differently in different situations based on what is best for the specific project, wall and the level of insulation needed.

Note and Update:

Some of the wall constructions shown above use foam insulation. Foam insulation generally provides a greater R-value than batt or cellulose insulation. However, based on recent evaluations of how various types of foam insulation are made and used, green builders are starting to use less foam insulation when possible. This is because a good deal of greenhouse gas is created in the manufacturing and installation of foam insulation products compared to other insulation such as cellulose insulation.

While foam insulation must be used in certain cases, the use of thicker double walls insulated with cellulose is now considered a better practice. the thicker double wall construction eliminates any need for foam boards around the outside of the sheathing. In cases where insulation needs to be used either to help prevent air or moisture infiltration and in situations where the insulation will be in contact with moisture, such as under the basement slab of concrete. foam insulation is still needed. It is also needed to fill and insulate certain areas such as crevasses

Get Social